Due to the unique design of the Novus Valve, following standards have been conformed.

UK

WRAS Approved Materials

Conformance to BS6920 Requirement

EU

Conformance to Directive (EU) 2020/2184 (DWD)

Lead-Free Product

EU Specific Marking

AS

Conformance to PN16 Product Testing

Conformance to Sluice Valve Standard

Water AS4020 Tested Product

All valves can be supplied in clockwise or anti-clockwise closing directions.

Due to the unique design and versatility of the Novus Valve, there is a range of suitable installation and use cases. The Novus Valve can be used as a line stop or an inline valve.

After installation and water main works are complete, the asset owner has the option to leave the valve bonnet installed or to replace it with a blank flange. If the need arises to operate a line stop after blank flanging, the valve bonnet can be re-installed under pressure by means of the temporary valve.

Below are engineering drawings of proven use cases of the S-Gate Valve technology.

NOVUS Valves have eliminated the following issues from existing methods

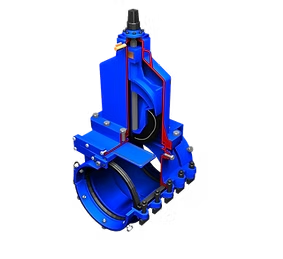

The NOVUS VALVE’s drilling method adopted removes only a minimal surface area to preserve the mechanical strength the main. The final result is a perfect cut, perpendicular to the surface across the entire cutting face.

Patent Technology 1

Our innovative design ensures greater durability and resistance to higher pressures. Steel spring allows a high-quality seal against the inner wall of the pipe. Newly formulated rubber ensures longer lasting flexibility.

With design shown right, our NOVUS valves adapts to uneven surfaces all around the pipe providing a seal on various pipe conditions.

Patent Technology 2

Developed in order to adapt to various calcium build up within the internal surfaces of the pipe.

Two Sealing points for greater shut on uneven surface

Our innovative design ensures greater durability and resistance to higher pressures. Steel spring allows a high-quality seal against the inner wall of the pipe. Newly formulated rubber ensures longer lasting flexibility.

The valve is coated with blue Resicoat R4-ES (HLF33K) fusion bonded epoxy (thermoset) in compliance with DIN EN 14901. All valves are exclusively available in clamp configurations.

Size Range:

DN80, 100, 150, 200, 225, 250, 300, 350, 375, 400, 450

500, 600

Allowable Operating Pressures:

1600 kPa, 16 Bar, 250 PSI

Connection Type:

DN80 – DN350

Clamp Type – 2 Piece System

DN400 – DN600

Clamp Type – 3 Piece System